Tag: Enhanced Productivity

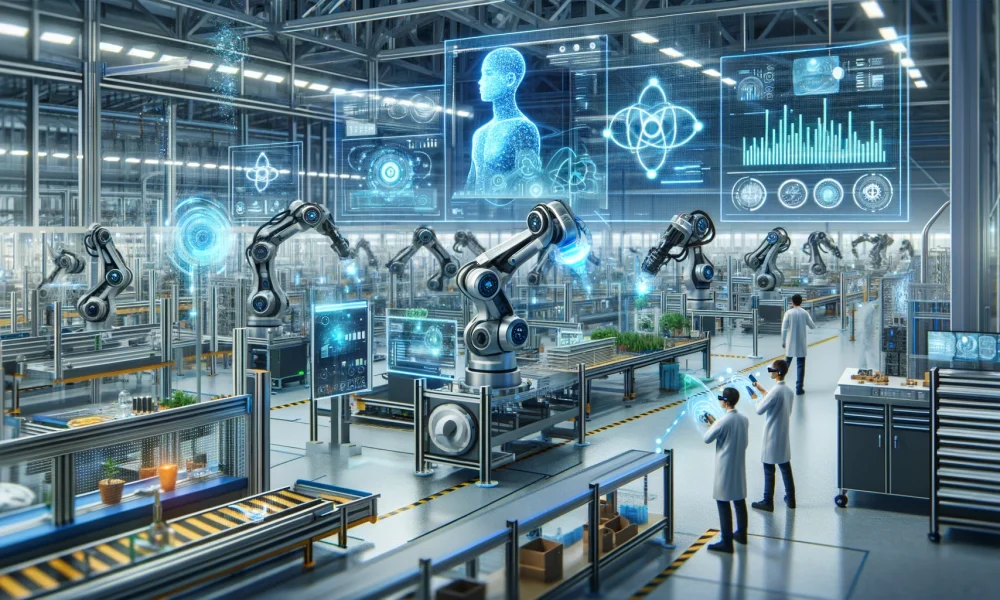

How Industry 4.0 Is Revolutionizing Modern Manufacturing?

The manufacturing world is undergoing a massive transformation, thanks to the emergence of Industry 4.0. Nicknamed the “fourth industrial revolution,” Industry 4.0 ...